Introduction

The recent and ongoing development in the technology of rechargeable lithium batteries has been steadily increasing their performance and making them more safe, reliable, cheap, and easy to manufacture. All of this resulted in an increasing popularity of rechargeable lithium batteries, not only in portable consumer electronics, but also in traction, energy storage, maritime, industrial, military, and aerospace and other applications, where the high energy density, negligible memory effect, low self-discharge rate, and long life cycle of lithium batteries are highly desired characteristics. Despite the advantages, all rechargeable cells of lithium chemistry have a very strict allowed voltage range and certain charging temperature limitations. If operated outside these limits, they will fail prematurely and pose safety risks due to reactive components inside them. Also, because the mentioned applications usually require battery voltage to be significantly higher than that of a single cell, several cells have to be connected in series to attain the desired voltage. This creates another problem: since lithium chemistry cells are very intolerant to overcharging, they do not have a natural equalization mechanism when connected in series (such as gassing in lead acid batteries), and any misbalance of charge between the cells will amplify with each cycle of operation if no countermeasures are taken, rapidly decreasing the usable capacity of the whole battery pack, and potentially causing its premature failure. In order to overcome these problems and to fully exploit the advantages of rechargeable lithium batteries, it is necessary to use an intelligent battery management system that can autonomously monitor the battery parameters at individual cell level in real time, and prevent them from going outside the safe operation limits. INNOLIA ENERGY has developed the BMS precisely for that purpose. It is a highly flexible, state of the art digital battery management system with a unique set of features and utility functions that is designed to make the use of rechargeable lithium batteries straightforward and virtually maintenance-free, regardless of the battery size, capacity, voltage, and other factors. This document covers all aspects of using the Emus BMS, and aims to provide the user with an in-depth knowledge about its core functionality and utility functions, as well as with information about its proper installation and configuration together with connection diagrams, examples, and recommendations – all in order to help to utilize all of its capabilities and prevent most commonly faced issues.

This document contains the specification for the INNOLIA 9S-15S (9-15 series) 100A Hardware BMS (battery management system) board for the LFP lithium battery cells.

9S to 15S hardware BMS has the following features, such as an overcharge, over discharge and overcurrent protection IC for a lithium-ion / lithium polymer rechargeable secondary battery. Lithium-ion / lithium-polymer rechargeable secondary battery overcharge each cell, over discharge, and discharge overcurrent, short circuits can be detected.

This supports 9 to 15 serial cells connected in series, and switches over to the desired no. of cells by sending High / Low signal to SEL terminal. This also provides the control terminals of output over discharge detection (SDC) and output over charge detection (SOC), which allows configuring an application with fewer external parts for 6 or more cells connected in series.

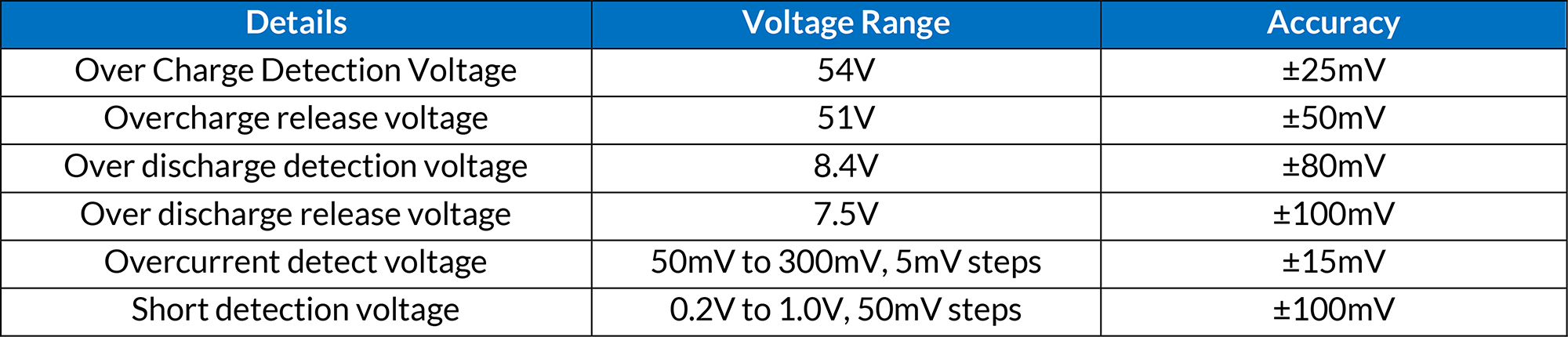

(1) Range and accuracy of detection / release voltage

(1) Low current consumption

Consumption current1

(Vdd),Vcell=4.4V Typ. 10.0µA, Max. 20.0µA

Consumption current2

(Vdd) , Vcell=3.5V Typ. 5.0µA, Max. 10.0µA Consumption current3

(Vdd) , Vcell=1.8V Typ. 1.5µA, Max. 3.0µA Consumption current1

(V5) , Vcell=4.4V Typ. 4.0µA, Max. 8.0µA Consumption current2

(V5) , Vcell=3.5V Typ. 3.0µA, Max. 6.0µA Consumption current3

(V5) , Vcell=1.8V Typ. 1.5µA, Max. 3.0µA

Absolute maximum ratings

- VDD pin VSS2−0.3V to +30V

- V5 pin V4−0.3V to VDD+0.3V

- Between the input terminals of voltage of battery −0.3V to +10V

- V− pin, CS pin VDD−30V to VDD+0.3V

- OV pin, DCHG pin VSS2−0.3V to VDD+0.3V

- SEL pin VSS2−0.3V to VDD+0.3V

- SDC pin, SOC pin VSS2−0.3V to VDD+0.3V

- Storage temperature −55ºC to +125ºC

- Operation temperature −40ºC to +85ºC

ACTIVE BALANCER :

This is inductive cell balancer based on ETA’s parent pending proprietary technology. Unlike conventional passive balancing technique, Active balancer utilizes a control scheme with an inductor to shuffle currents between two cells until the cells are balanced. Due the switching nature, the heat and power dissipation generated in conventional linear balance technique are greatly reduced. The balance time is also significantly reduced due to higher balancing current not being limited by package thermal dissipation. This consumes only 2µA ultra-low current from batteries in standby mode, extending the battery shelf time. The final balanced voltages of both cells are also highly accurate which enhances the performance and life time for the batteries connected in series. This can also be used in multiple cells stacking with even number of cells. This includes protection features similar to precondition in battery charging, that is when one cells voltage is grossly lower than the other, and the balancing current is reduced to a safe level until the lower voltage cell is charged up.

Features :

- Inductive switching control scheme

- Up to 92% charger transfer efficiency

- Accurate Balanced voltages down to 30mV

- Auto detect unbalance and auto balance

- Low sleeping supply current, 2µA

- Precondition balancing current

- Status indications

- Battery over voltage protection